I decided that the screw used to lift the weight on the Bandaid dispenser was unsightly and needed some dressing up. I also wanted to try to turn some brass on the lathe.

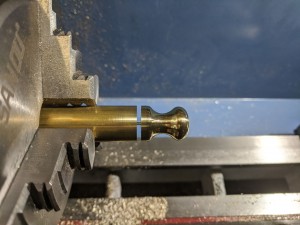

I figured a nice Brass Knob would look good. Something with a nice smooth curve and a polished look. As I thought about it, however, I realized using the Lathe cross slide controls would make it very hard to get a smooth continuous curve. Reading up on this kind of turning I learned that smooth curves like this, if not cut on a CNC lathe, are generally turned freehand. I’ve done enough wood turning so I thought I’d give it a try…

Heck, that wasn’t so hard… Let’s continue…

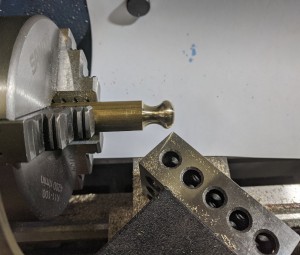

Here is the setup of the support I used to freehand turn the brass knob. The carbide turning gouge rest on the 123 block held in place with the magnet.

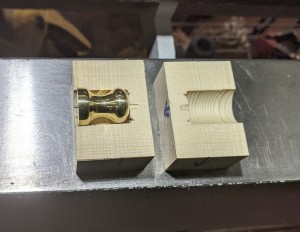

Finally, with the knob left with just a little nub at the bottom of the base, I needed to make a clamp that would hold the knob while I machined the base. I couldn’t use the vice directly on the soft brass, so…

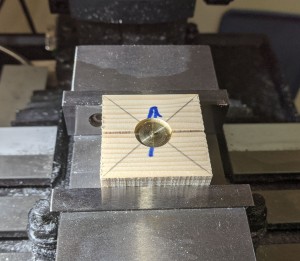

First time I used the Boring head with the new MT2 post I got as a Christmas present. I needed the adjustable boring head to machine a two level hole exactly the same diameters as the brass knob.

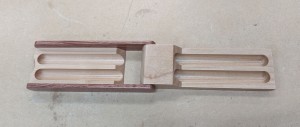

Cross-section view of the clamp. Note the two tiers of diameters so the knob is held tightly at top and bottom without marring the polished surface.

Here is the knob, clamped on the Mill so that the nub can be milled off and a threaded hole can be machined exactly into the center of the base.

And here is the result!